Constructed and implemented an enhanced Maintenance Management Operating System (MMOS) for FMS Diesel Mobile Maintenance (7)

MMOS Audit System & other activities

Keywords

- MOS

- Availability

- MTBF

- MTTR

- Performance Management

- CMMS Data Improvement

- Effective Inspections

- Bad Actor Management

- Shift Change Management

- Work Management Process (planning)

- Supply Chain Stockout Alarm System

- Pre-PM

- PM Routines

- SMART PM

- 5´s

- Pit Stop Green Flag System

- Flexibility Matrix

Driver Goal

- To improve efficiency, predictability and reliability within the Mobile Maintenance area and equipment.

- To improve Maintenance planning and operational effectiveness.

- The delivery of the training and coaching required to enable the changes in behavior needed to ensure the sustainability of the operational improvements.

Results

Up to Week 16

Up to Week 16

- Achieved Short range drilling availability to 93% for June. 9 points above the target, and long range drilling availability to 87% for June. 3 points above the target.

- Achieved MTBF 17 hours for June. 5 points above target.

- Early Shifts Inspection Program has generated 44 minute average of additional potential scoop utilization.

- 3.33% of real utilization for Scoops generated by improved shift management initiatives.

- Stablished a 40 min std effective inspections.

- Achieved 100% lubrication compliance for drills for the first time and 100% for scoops for 3 weeks.

- Manloading has raised to 77% avg. from 40% before generating 700 MH avg of real executed hours.

- 100% Pre-PM and Perfect PM compliance for equipment.

Issue

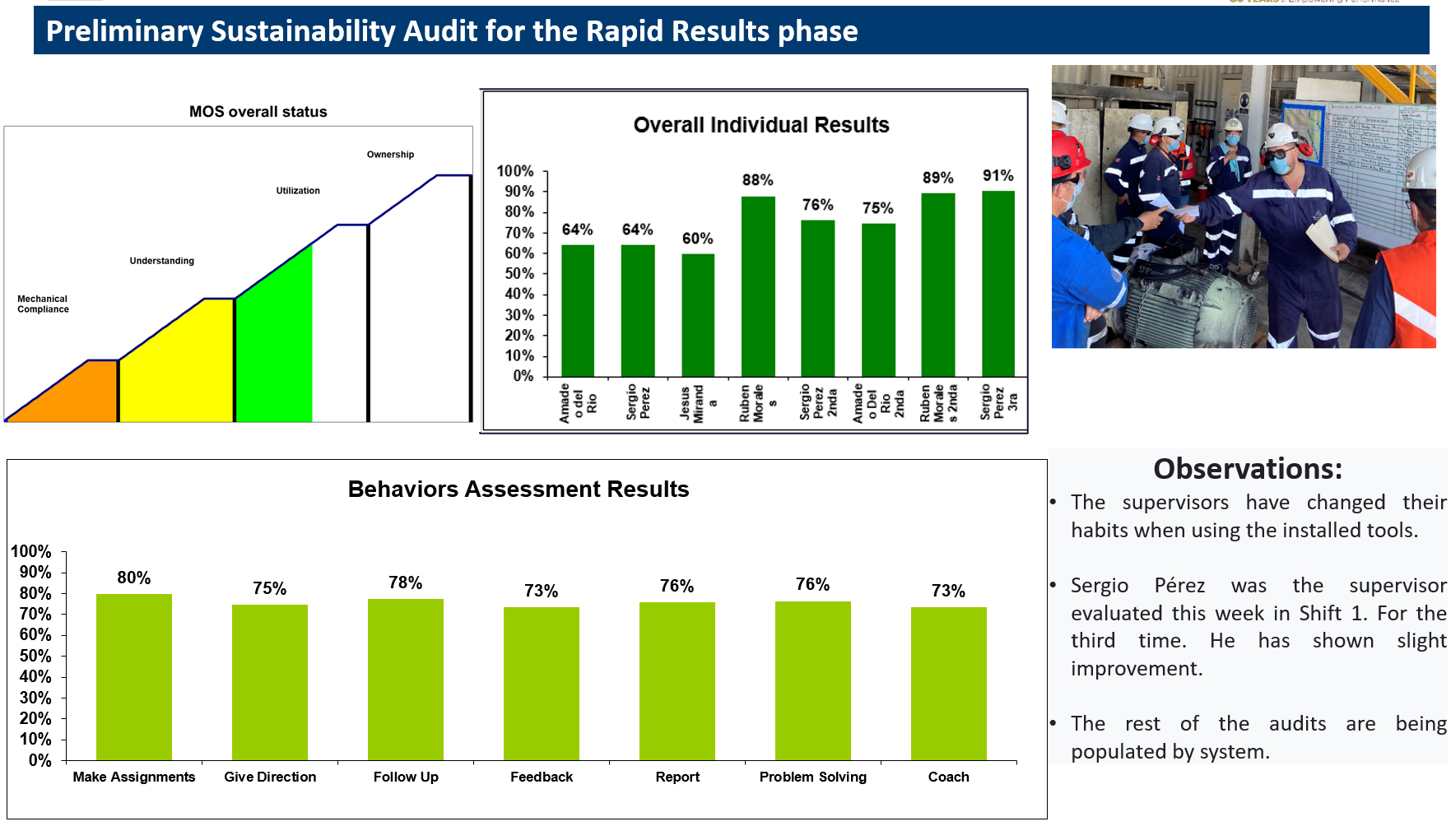

- Audit System installed for Supervisors.

- Planners Audit System at 80%

- Two of the supervisors are already in the Ownership phase.

Other activities

- Program 5's and Project for Signage and Parking Management Improvement

- Pit Stop Green Flag System for communication improvement using visual Aid

- Flexibility Matrix to Develop an improved Training Competences Program